5 Simple Statements About gearbox cvt Explained

5 Simple Statements About gearbox cvt Explained

Blog Article

Pulley-based CVTs are known for their efficiency and smoothness, toroidal CVTs for his or her large torque ability, and hydrostatic CVTs for their longevity and specific Command in heavy equipment.

CVT gearboxes can develop a droning sounds that retains continuous, rather than escalating or reducing with motor speed. This can be a tiny bit disconcerting for some motorists, and takes some receiving utilized to.

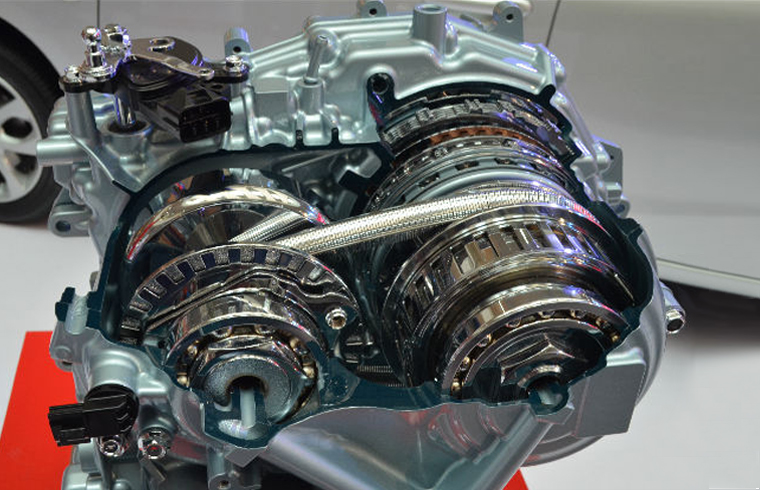

CVT in the Claas Mercator Merge harvester. The pulley's successful diameter is improved by pushing the two conical discs both towards or from one another.

With this sort of an arrangement, as much more oil is diverted by opening the valve, the powerful displacement in the pump is reduced and fewer oil is sent to the motor, triggering it to turn much more little by little. Conversely, closing the valve will reduce the volume of oil getting diverted, escalating the successful displacement on the pump and triggering the motor to turn a lot more speedily.

CVTs are a number of the smoothest gearboxes, also. Without any physical gears to swap involving, there’s no jolt or pause because it modifications up from the gears like some conventional automatics. Acceleration is continual and linear, and may make the driving knowledge a lot more cozy.

It is very practical in mountainous parts. Just take into account that these transmissions can have a significant price tag tag on equally the First acquire and restore Expense. So it is necessary to ensure that it is roofed underneath guarantee. Edmunds details out the CVT edge lies in its simplicity.

The total variety of mechanical pieces within a CVT is lesser than in an average World-gearset transmission. Devoid on the common phalanx of gears and cogs, a CVT box works by using a brace of adjustable conical pulleys attached to your steel chain or belt.

Although this type of procedure appears greatly various, most of cvt the components are analogous into a belt-and-pulley procedure and result in the exact same results -- a continually variable transmission. This is how it really works:

Programs: Perfect for weighty-duty apps like agricultural and industrial machinery. Its robustness and specific control allow it to be well suited for gear that needs reliable electricity and toughness.

In contrast to standard automated transmissions, repeatedly variable transmissions haven't got a gearbox which has a set variety of gears, meaning they haven't got interlocking toothed wheels.

Conventionally programmed CVTs because of the absence of any stepped gear perception might cause the motive force to misinterpret their standard working efficiency as a sign of unreliability.

With the late eighties, the CVT had entered the mainstream due to Subaru. In contemporary times, virtually every manufacturer has a minimum of one particular design by using a repeatedly variable transmission.

The principal clutch is a complicated form of centrifugal clutch and is usually mounted to your output end in the motor crankshaft. The clutch has two sheave faces; one that is laterally mounted (stationary sheave), and one which can move in and out to have interaction the belt (moveable sheave).

There is a next, fewer commons variety of CVT that employs a series of discs and rollers, but it surely operates on comparable concepts.